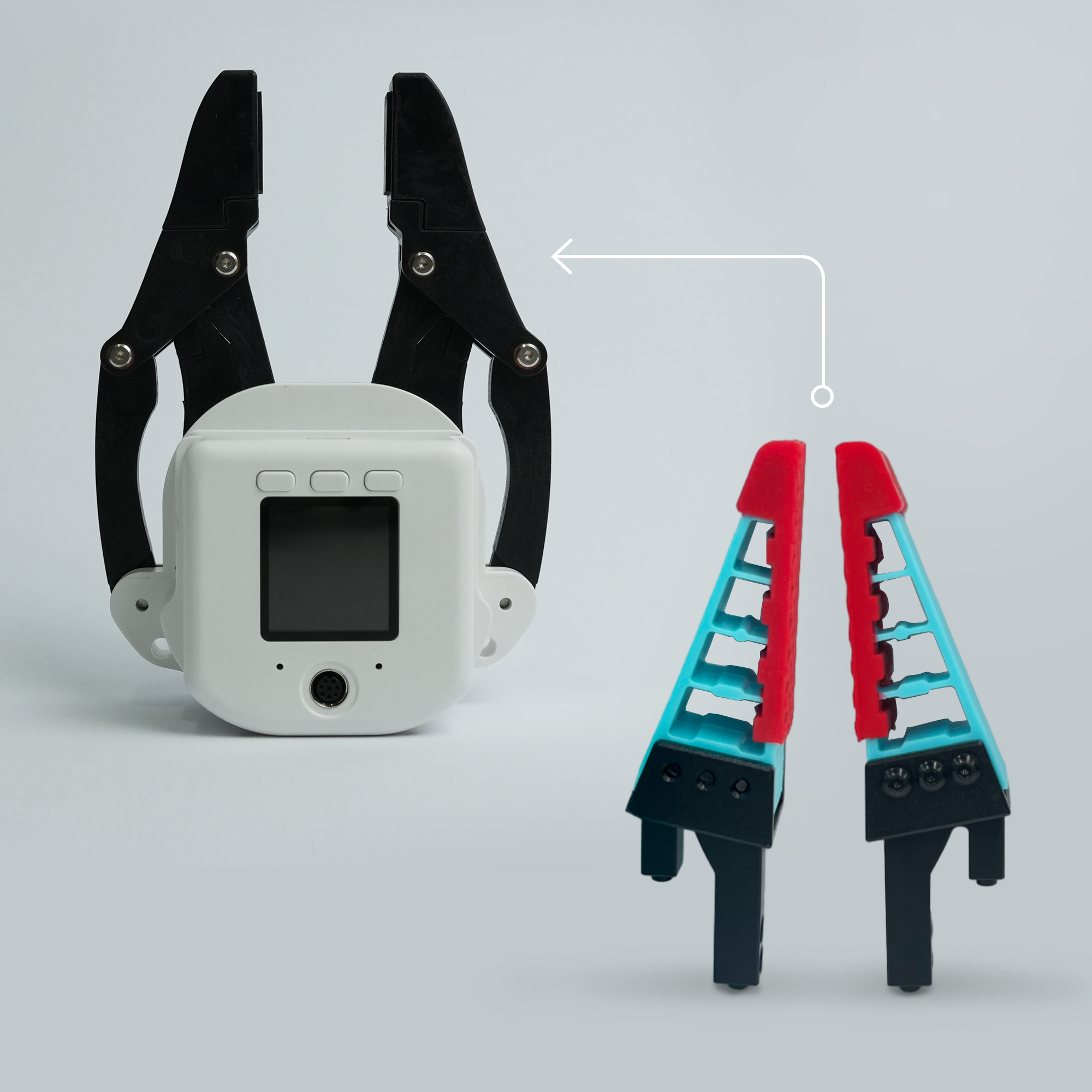

myGripper F100 Force-Controlled Gripper for Cobot 320/Pro 630/Mercury Series, 2-in-1 Design with Bonus Flexible Fingertips (Replaceable)

If you want to know more product information such as edu version, please contact us directly.

The myGripper F100 Force-Controlled Gripper is currently in limited stock, with an estimated dispatch time of one month.

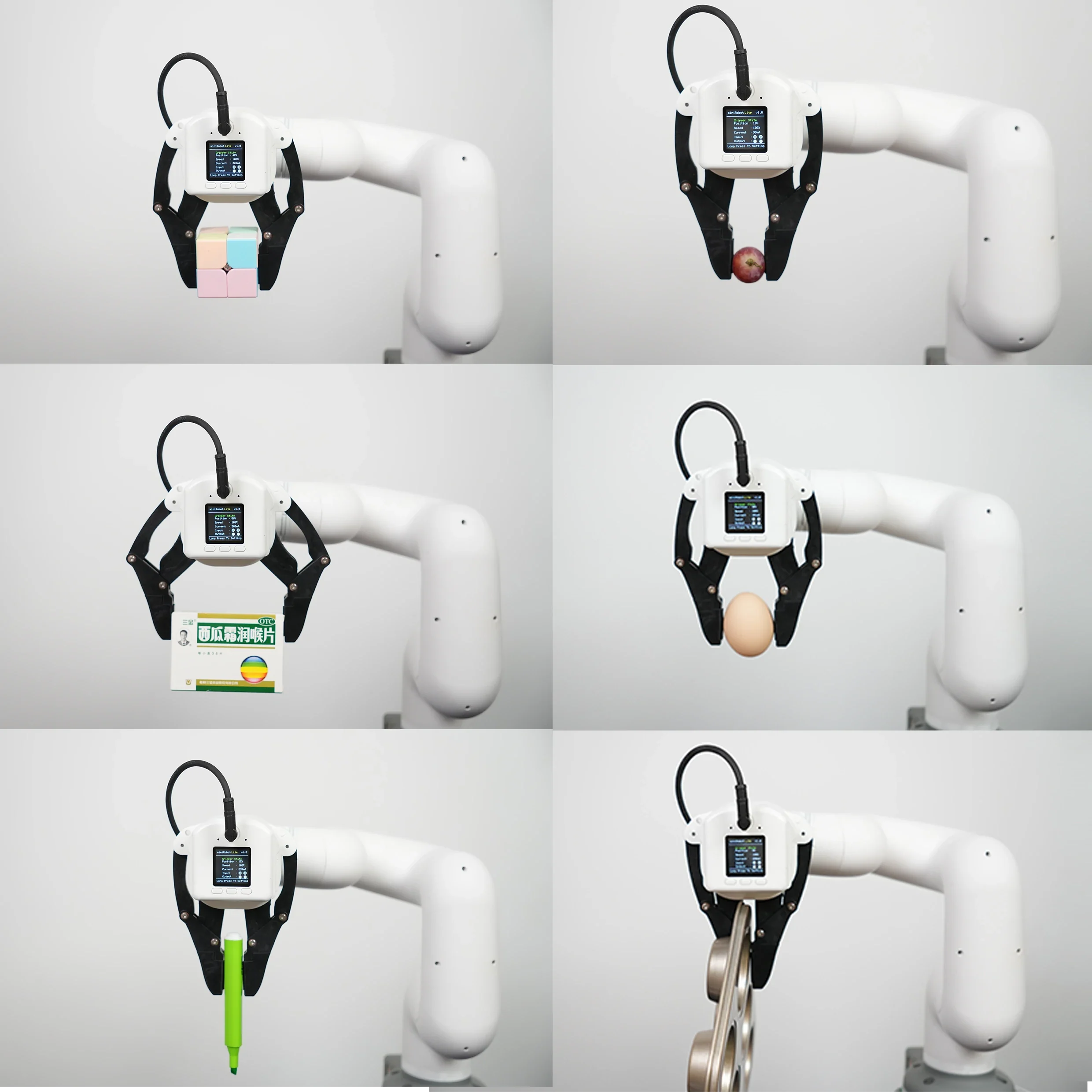

The myGripper F100 is a high-performance robotic end-effector designed for versatile gripping tasks. It can be used for myCobot 320 M5Stack 2022¡¢myCobot 320 PI 2022¡¢myCobot Pro 630¡¢Mercury Series. Manufactured with PC and PBT materials using precise injection molding, it ensures durability and reliability.

This force-controlled gripper offers a highly adjustable stroke range of 0-100 mm (default fingertip spacing) and features multi-level torque settings to adapt to a wide spectrum of gripping force requirements. Engineered for precision, it boasts a rated payload of 500 g and a repeatable positioning accuracy of ¡À0.5 mm. It's an excellent solution for a variety of robotic gripping tasks, ensuring reliability and adaptability in dynamic automation environments.

Application Scenarios

Laboratory Operations

Grasping and moving test tubes, containers, and other items in research experiments, ensuring safety and accuracy.

Educational Demonstrations

Serving as a teaching tool to help students understand robotic gripping principles and develop practical skills.

Material Handling

Transporting materials of various specifications in simulated production lines or warehouses to improve efficiency.

ultraArm P340 Video

Product Highlights

Product Package

|

myGripper F100 *1 |

| USB Data Cable *1 | |

| USB to 485 Module *1 | |

| myCobot Pro Flexible Fingertips *2 | |

| M5 USB Firmware Upgrade Module *1 | |

| 8PIN Aviation Plug to Open Wire (2m) *1 | |

| Double-Head 8PIN Aviation Plug Connection Cable *1 |

Software Programming

The myGripper F100 offers a standardized robot driver library that can be easily downloaded and installed via PyPI. It supports querying joint angles, Cartesian coordinates, encoder positions, speed data, and more. Compatible with both ROS1 and ROS2, it includes support for the RVIZ simulation environment, allowing users to display the robot arm's state and collect real-time data.

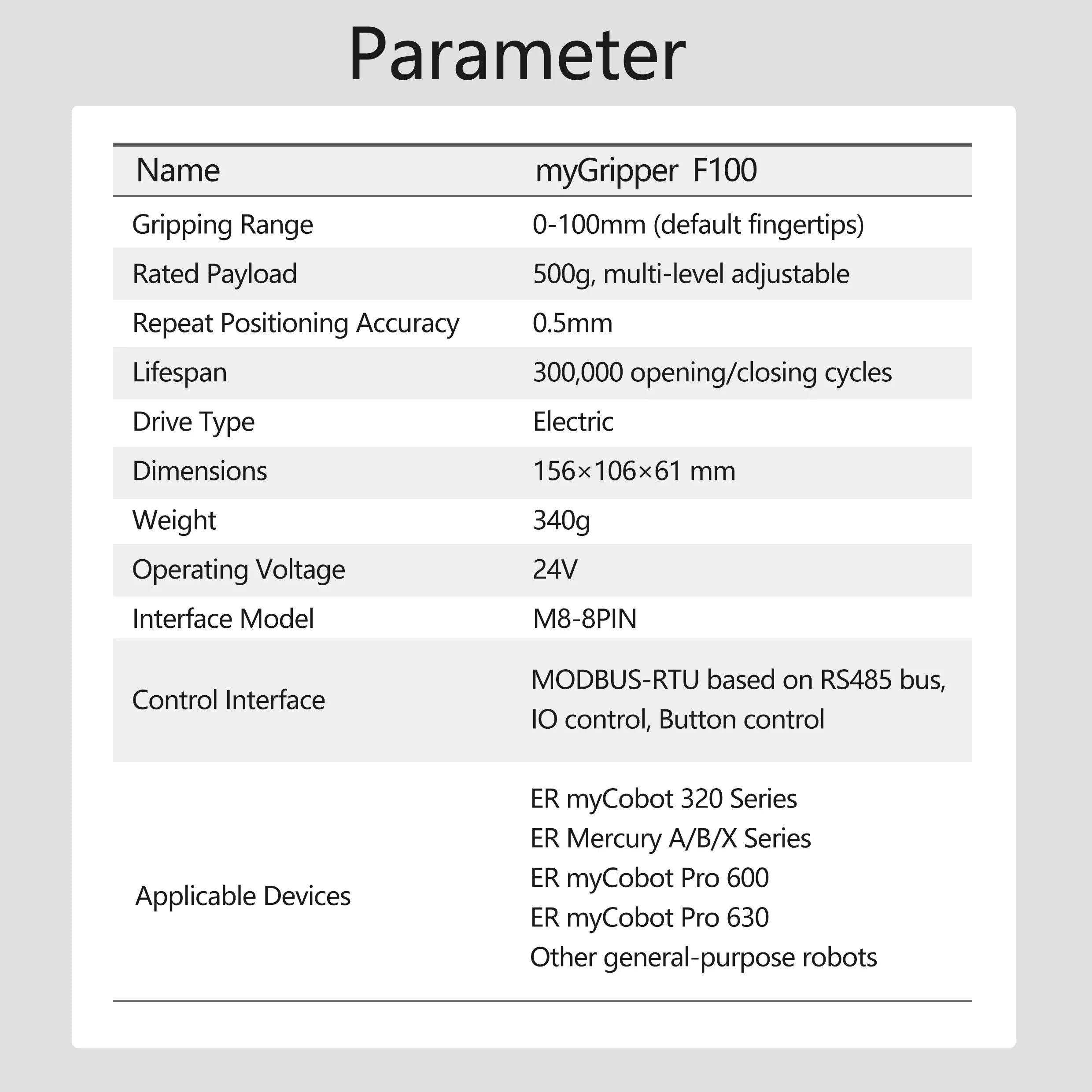

Product Parameters

| Name | myGripper F100 | ||||

|---|---|---|---|---|---|

| Material | PC, PBT | ||||

| Manufacturing Process | Injection molding | ||||

| Stroke (Diameter) | 0-100 mm (default fingertip spacing) | ||||

| Rated Payload | 500 g, multi-level adjustable | ||||

| Repeated Positioning Accuracy | ¡À0.5mm | ||||

| Lifespan | 300,000 opening/closing cycles | ||||

| Drive Type | Electric | ||||

| Transmission Method | Gear + linkage | ||||

| Dimensions | 156¡Á106¡Á61 mm | ||||

| Weight | 340 g | ||||

| Operating Voltage | 24V | ||||

| Interface Model | M8-8PIN | ||||

| Mounting Method | Screw-mounted | ||||

| Operating Environment Requirements | Normal temperature and pressure | ||||

| Control Interface | 5x5 LED matrix | ||||

| Communication Frame Rate | MODBUS-RTU based on RS485 bus, IO control, Button control | ||||

| Robot Compatibility |

|